All refinishing jobs are highly dependent on your exact needs and preferences. Call or email GHA for a quote.

GHA offers two grades of refinishing Restoration and Conservation.

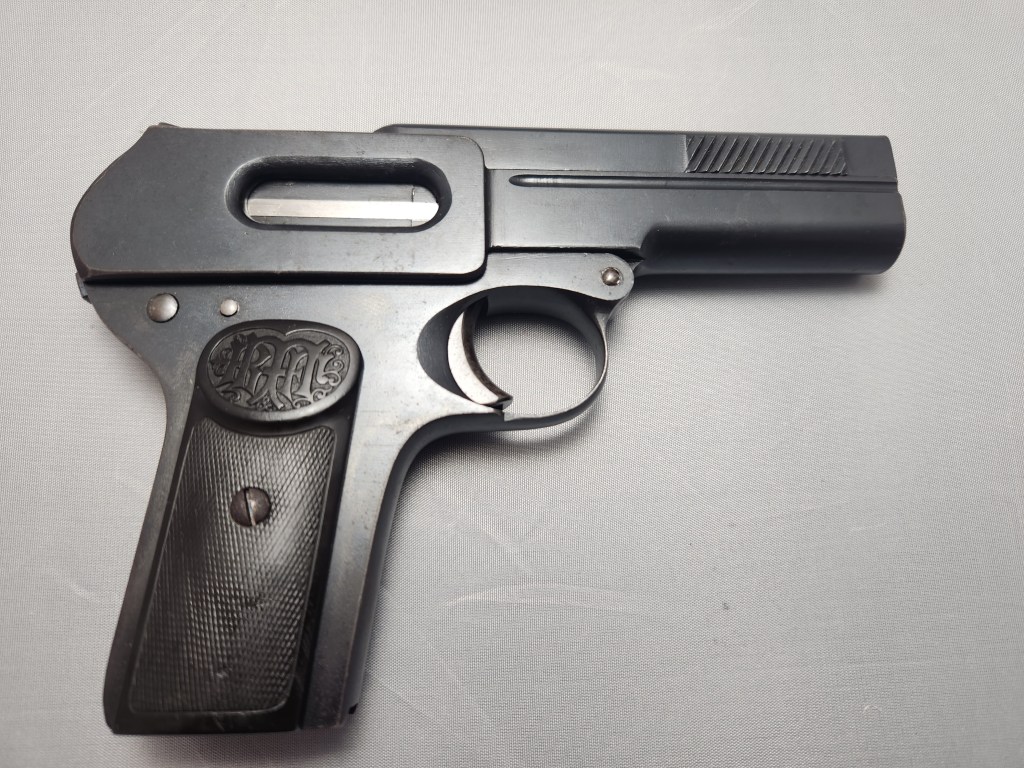

Conservation Grade: Newly applied bluing over existing metal. Metal is only lightly sanded and polished in an effort to preserve all original markings and stampings. Pitting in the metal surface will likely not be totally removed depending on depth. Conservation grade finishes tend to be cheaper than restoration grade finishes. Conservation grade finishes are recommended for those looking to preserve as much originality as possible.*

Restoration Grade: Newly applied finish over re-polished or re-sanded metal. Restoration grade finishes include potentially heavier sanding and polishing in order to remove pitting and defects in the metal surface prior to refinishing. Depending on depth of pitting in the metal surface, the detail and clarity of stampings may suffer. Restoration grade finishes tend to be more expensive.*

* Finishing grades do not apply to parkerizing or spray on finishes.

Types of Finishes

Rust Bluing: One of the oldest forms of bluing. Consists of many layers of controlled rust that is converted into a hard oxide finish, creating a beautiful satin-semi gloss blue that ranges in color from charcoal to deep blue. Due to the nature of rust bluing, getting a mirror like finish from rust bluing is nearly impossible. Rust bluing is the most durable form of bluing, but is also the most time consuming to apply. This form of finish was used up until approximately the 1930’s, when hot salt bluing largely replaced it. This finish is found on WWI era P-08 Lugers, C-96 Broom handles, Gew-98 Rifles, Enfield rifles, Webley Revolvers, U.S. Krags, U.S. Trapdoor Springfields, and many more Pre-WWII firearms. Rust bluing is also commonly found on U/O and SXS shotguns with soft soldered ribs, where hot salt bluing would damage the solder joints between the ribs. Due to the labor and time required to complete a rust bluing job, rust blued finishes tend to be the most expensive.

Hot Salt Bluing: The current standard for bluing. Hot salt bluing is the most common form of bluing found on firearms. Firearms are polished to whatever degree deemed necessary, then dipped into a hot caustic salt solution to form the bluing. Hot salt bluing is favored for its rich blue color, and its ease of application, especially at an industrial scale. Finished sheens can range from a flat bead blasted finish to a highly polished, mirror-like finish, depending on the polishing of the substrate. Hot salt bluing is found on almost every post WWI to modern era firearm. Due to its ease of use, the majority of the cost arises from the level of polishing and metal prep required, making it one of the most cost effective refinishing options. One issue with hot salt bluing is its lack of tolerance for high nickel content steels, making it difficult to reblue many post-64 Winchesters, and even some of pre-64 Winchesters. For Winchesters, we can offer special pre-treatments at cost, or other finish types.

Nitre Bluing: Also known as fire bluing or strawing. This finish is most commonly found on screws and small parts of firearms. Nitre bluing is formed by placing polished parts in a bath of molten salts in excess of 600F. Nitre bluing is an extremely thin surface finish, making it the weakest form of finishing available. Examples include straw triggers on P-08 Lugers, the deep blue extractors and bolt stops of C-96 Broomhandles, and many other small parts of pre-WWII firearms. Due to the extreme heat involved, nitre bluing is used exclusively on small parts, where impact to heat treatment is not crucial.

Parkerizing: Also known as phosphating. Parkerizing creates a light to dark gray finish on metals. Parkerizing is applied by first sand blasting the surface, then immersing the parts in a bath of boiling phosphoric acid solution. Due to the sandblasting that is a REQUIRED step for forming manganese phosphate, it is not possible to create a polished form of parkerizing. This finish type is found on WWII era U.S. firearms including M1 Garands, M1903A3 Springfields, M1 Carbines, M1911A1’s, M1919 Medium Machine Guns, and many more. Parkerizing is one of the easiest to apply finishes, making it also one of the most economical finishes for the customer.

Rust Bluing Contact us for quote

Hot Salt Bluing Contact us for quote

(Coming Soon)

Manganese Phosphate Parkerizing Contact us for quote

Spray on finish Cerakote/Duracoat Contact us for quote

(Single color per part)